Got a new project delivered. Not sure what year though?

Got it delivered on Saturday and stripped down Sunday! Had a sink and stove, but did not see a furnace.

I am thinking to do the following and appreciate any advice for this build:

Got it delivered on Saturday and stripped down Sunday! Had a sink and stove, but did not see a furnace.

I am thinking to do the following and appreciate any advice for this build:

- Make it a shell that rest on the truck's bed rails

- Chop the frame so that the base is 6.5' to fit my truck (cabover nub will go full size)

- Chop most of the back wall so that I can make a hatch opening and keep my tailgate

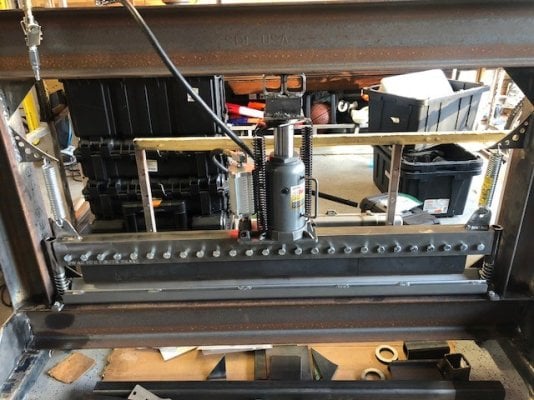

- Fabricate Jack Brackets

- New Canvas

- Will incorporate solar and quick release appliances ran from LiPo (i.e. fridge)

- Not sure on lift mech, probably will avoid re-making panels.

- Not sure on windows, but will update these too

- Not sure on skin, but love FWC's Silver Spur look and Project M diamond plate

- Not sure about interior on this one