camelracer

Contributors

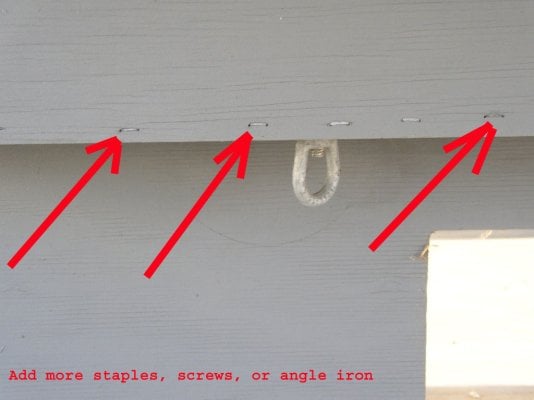

I've only had the camper off the truck a couple of times so I haven't paid much attention to the floor pack. Now that I have it off I did an inspection and noticed that the horizontal section of the floor pack in the area of the tie down rings is pulling away from the vertical section. I'm not sure if this is normal or not so I'm asking the WTW experts.

I don't know how FWC assembles this area. Is it just the staples holding it together or is the joint also glued? Maybe Stan can answer this question.

I'm thinking of pushing the horizontal section back in place and running some screws in where the staples are but I'm not sure about screwing into the end grain of the plywood. I don't want to make the problem, if there is a problem, worse. Woodworking is not my forte. Any help would be appreciated.

I don't know how FWC assembles this area. Is it just the staples holding it together or is the joint also glued? Maybe Stan can answer this question.

I'm thinking of pushing the horizontal section back in place and running some screws in where the staples are but I'm not sure about screwing into the end grain of the plywood. I don't want to make the problem, if there is a problem, worse. Woodworking is not my forte. Any help would be appreciated.