Hey All, I just bought a fwc bronco for $200 that was in pretty rough shape, but I knew that going in. I mostly just wanted it for the skeleton and a template to build onto. I've dug through a ton of the forums and chats on here prior to buying, but wanted to start a topic to see if anyone is interested in following the build and I also know that folks on here will have great ideas when during roadblocks and brain farts. I'm located just south of Denver, so if anyone has tips for local vendors, that would definitely be appreciated!

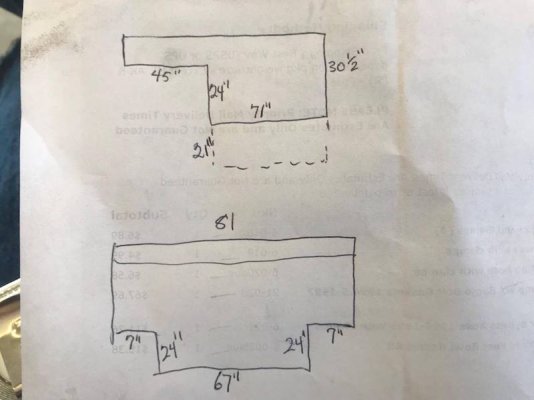

I'm building a floor pack and front frame to make it fit my 1500 short bed (5'9") Silverado. I made the floor pack from 3/4" marine grade plywood and plan to paint it with heavy duty dock paint. This week I plan to lay out and start welding the aluminum frame with a neighbor experienced in TIG welding. Bought some 6063-T52 square aluminum tube online in 1"x1" and 1"x2" and found pictures from ski3pin during their camper build on how the frame and floor pack is all mounted together. If anyone hasn't seen this build out, it's awesome.

http://www.wanderthewest.com/forum/topic/8078-building-our-new-camper/

Some of my main thoughts I'm still pondering are below. Happy to accept any advice or comments along the way too. I'll add more questions and builds as I go further into it.

- I hope to use filon siding to replace the badly dented aluminum siding (Colorado hail storm actually pierced the aluminum). I'm unsure whether I should mount it to a luan backer board or if this stuff is sturdy enough to adhere to the aluminum and rigid foam insulation (and rivet around the edges?).

https://www.ebay.com/i/292661593581?chn=ps

- Thoughts on the roof? It's badly dented, but I coated it with the hose and didn't see any signs of a leak. There's also no water damage on the insides, only on the front where it attached to the bronc, the exposed floor portions, and under the bed where it was exposed to the elements. I plan to just paint the roof back to white with the rubber roof paint for aesthetics and to add another coat for assurance.

- Any thoughts on mounting a propane tank to the outside to save space inside? Can this freeze in the winter? I am insulating all sides to make it a 4-season camper.

- Does anyone know where to get a new side window? I've scoured eBay and most Rv sites that came up within the first 4 pages in Google searches, but nothing is close to the 60" x 16" dimensions. I'd love for a long awning style window and am open to modifying the frame to accommodate something slightly different.

I also built a tow behind camper last year and sold it for a profit on hardware (definitely not labor...), so I'm not afraid of 90% of the work required. Honestly, resewing the canvas eventually is the scarier part, but Tim Morrissey's videos on youtube are helpful calm my nerves there. With the last camper I basically built everything three times to finally get it right

I'm building a floor pack and front frame to make it fit my 1500 short bed (5'9") Silverado. I made the floor pack from 3/4" marine grade plywood and plan to paint it with heavy duty dock paint. This week I plan to lay out and start welding the aluminum frame with a neighbor experienced in TIG welding. Bought some 6063-T52 square aluminum tube online in 1"x1" and 1"x2" and found pictures from ski3pin during their camper build on how the frame and floor pack is all mounted together. If anyone hasn't seen this build out, it's awesome.

http://www.wanderthewest.com/forum/topic/8078-building-our-new-camper/

Some of my main thoughts I'm still pondering are below. Happy to accept any advice or comments along the way too. I'll add more questions and builds as I go further into it.

- I hope to use filon siding to replace the badly dented aluminum siding (Colorado hail storm actually pierced the aluminum). I'm unsure whether I should mount it to a luan backer board or if this stuff is sturdy enough to adhere to the aluminum and rigid foam insulation (and rivet around the edges?).

https://www.ebay.com/i/292661593581?chn=ps

- Thoughts on the roof? It's badly dented, but I coated it with the hose and didn't see any signs of a leak. There's also no water damage on the insides, only on the front where it attached to the bronc, the exposed floor portions, and under the bed where it was exposed to the elements. I plan to just paint the roof back to white with the rubber roof paint for aesthetics and to add another coat for assurance.

- Any thoughts on mounting a propane tank to the outside to save space inside? Can this freeze in the winter? I am insulating all sides to make it a 4-season camper.

- Does anyone know where to get a new side window? I've scoured eBay and most Rv sites that came up within the first 4 pages in Google searches, but nothing is close to the 60" x 16" dimensions. I'd love for a long awning style window and am open to modifying the frame to accommodate something slightly different.

I also built a tow behind camper last year and sold it for a profit on hardware (definitely not labor...), so I'm not afraid of 90% of the work required. Honestly, resewing the canvas eventually is the scarier part, but Tim Morrissey's videos on youtube are helpful calm my nerves there. With the last camper I basically built everything three times to finally get it right