Stan@FourWheel posted a picture of one of his aluminum frames next to an image of a buildup of a prototype composite camper. He asked about the cantilever structure. I wondered if a few hundred pounds of static load on the overhang was an adequate test. Let me submit another point of inquiry in connection with composite resin construction, namely “fastening”.

“Gougeon Brothers on Boat Construction” is a treatise on building boats. Gougeon Brothers produces and sells West System Epoxy, premium composite fillers, glass cloth of many types and weights, and other products used in boat construction. Their products are recognized as some of the finest available. Gougeon Brothers has worked out many of the techniques for construction and handling of epoxy resin composites through years of testing and practical application. For years, they published a journal on the subject of building many different composite structures and are one of the most respected sources of information on the subject that is known.

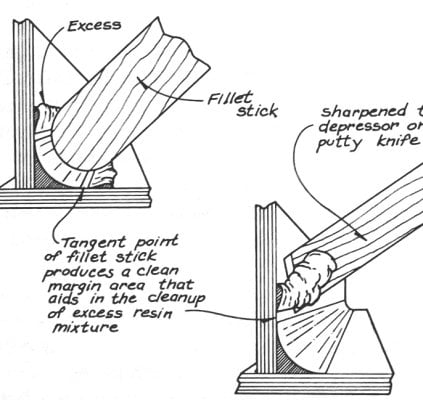

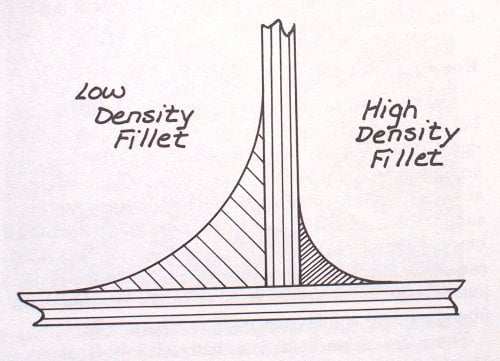

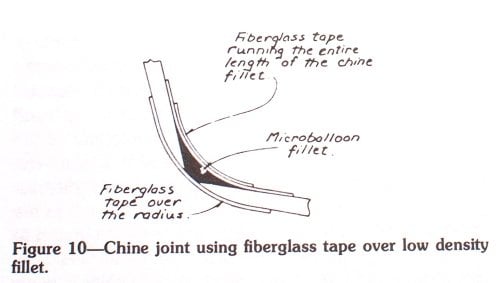

Following are 3 illustrations from their book, just to whet appetites for the quality of their published work. A copy of their book on boat building would be useful to camper builders, especially those using composite resins exclusively. Maybe the builders of the composite campers have already studied this material. I hope so.

“Gougeon Brothers on Boat Construction” is a treatise on building boats. Gougeon Brothers produces and sells West System Epoxy, premium composite fillers, glass cloth of many types and weights, and other products used in boat construction. Their products are recognized as some of the finest available. Gougeon Brothers has worked out many of the techniques for construction and handling of epoxy resin composites through years of testing and practical application. For years, they published a journal on the subject of building many different composite structures and are one of the most respected sources of information on the subject that is known.

Following are 3 illustrations from their book, just to whet appetites for the quality of their published work. A copy of their book on boat building would be useful to camper builders, especially those using composite resins exclusively. Maybe the builders of the composite campers have already studied this material. I hope so.