Hi Pawpaw, I would definitely do it Ripper's way if I had to do it again. I thought I would do too much damage to the sheet metal going that route but since I banged it all up anyway (from the inside) I am probably going to reskin at a later date. His idea is just better. I did visit with Bryan Wheat at the new factory in Winlock and he offered to sell me the new sheet metal "kit" for the top. I am hesitant to do that as I am sure my outside dimensions changed a little and would hate to spend the money and end up "short". Maybe I will ask him to cut it all a little long, hopefully not driving up cost too much over the $900 or so. I may just buy more material from Hemet and do it all by hand.

My idea was to use the skin as a sort of template as I built the inside back up again. Less precise than I might have hoped. Oh well. It basically worked out even though my dims are slightly "custom" now.

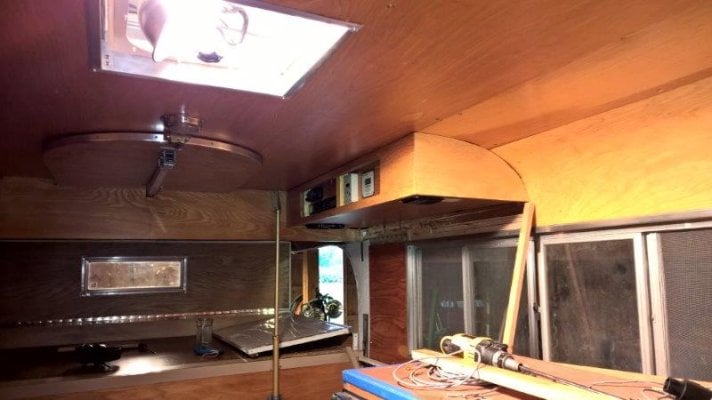

I have attached a few pics of the structural work. You can see I started by tearing out too much, sistering with strips of 3/4" marine ply and finally with some steel and aluminum tube (what was on hand at the time) because the roof was so flexible I felt it needed something more.

The rest is just doubled up 3/4" marine ply to make up the missing pieces, staggering the joints as much as I could. Pocket screws, plus some Simpson Strongtie brackets. I would not do those brackets again. Too heavy, too much drilling headache later, dubious added strength.

The roof is very heavy now of course so I have separate valves controlling each ram and a new hand pump. It works. If a tad overkill.