Riverrunner

Senior Member

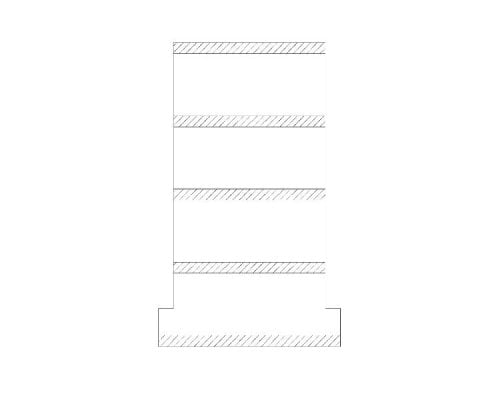

Does anyone know the thickness of the plywood used for the floor an 05 Grandby? I need to start building my "lift kit" for the new to me camper and need to know how much wood I have to screw too and not come up throught the floor. Some of the build photo's I've seen looks like more than 1/2"....maybe 3/4"?

Also...if anyone happens to have the dimensions of the floor, that would be cool too. I'm assuming the bottom is 48". The rear (wide part at the tailgate is 58 or 59"?

I'd like to butcher boards this weekend, get them painted, pre-drilled and get screws so I'm ready to roll. Since I wont have the jacks mounted for a while (another project) I need to make the lift permanent when I got get it.

I'd call the FWC but most of them are camping at the FWC rally this weekend. Thanks!

Also...if anyone happens to have the dimensions of the floor, that would be cool too. I'm assuming the bottom is 48". The rear (wide part at the tailgate is 58 or 59"?

I'd like to butcher boards this weekend, get them painted, pre-drilled and get screws so I'm ready to roll. Since I wont have the jacks mounted for a while (another project) I need to make the lift permanent when I got get it.

I'd call the FWC but most of them are camping at the FWC rally this weekend. Thanks!