RobNE

Advanced Member

- Joined

- Jan 4, 2009

- Messages

- 56

Hey All,

I looked through a number of topics talking about these dammed rusty brackets... the must be the sacrificial anode of the entire camper. I think my camper looks decent, but I always notice those brackets!!!

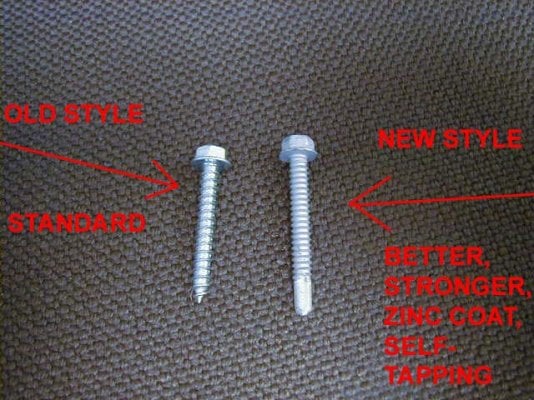

So i figured I would take them off and hit them with a wire wheel and then prime/paint. That alone seems like its going to take days of work to get them cleaned up. In addition, I broke off 5 of the lag screw heads.

Fisherman, I saw in one of your posts that you had broken off a few. How did you fix them? A small easy-out or the like?

What do most people do? Should I take them to a powerder coating shop and Will they have the means to clean them first (acid bath?) before powder coating?

Rob

ps: this bracket was probably one of the better looking ones...

I looked through a number of topics talking about these dammed rusty brackets... the must be the sacrificial anode of the entire camper. I think my camper looks decent, but I always notice those brackets!!!

So i figured I would take them off and hit them with a wire wheel and then prime/paint. That alone seems like its going to take days of work to get them cleaned up. In addition, I broke off 5 of the lag screw heads.

Fisherman, I saw in one of your posts that you had broken off a few. How did you fix them? A small easy-out or the like?

What do most people do? Should I take them to a powerder coating shop and Will they have the means to clean them first (acid bath?) before powder coating?

Rob

ps: this bracket was probably one of the better looking ones...