M1010 Mike

Senior Member

Well, we took out our new Ram truck and FWC Grandby for it's first shakedown run. Did a little over 200 miles total, of which about 40 of that was offroad. Had a good time and enjoyed the camper.

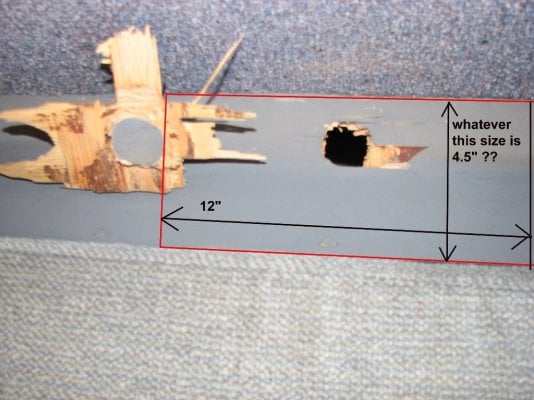

I did find when I got home that the front pass. side turnbuckle was laying in the bed. Curious I stuck my hand up to see if the camper mounting point was still there and was greated with torn wood and the mount loop at an angle. The turnbuckle was still adjusted (not loosened) as I use a jamb nut to prevent that. I haven't taken the camper off yet but I know I have some serious repairs to do. Kind of a bummer for our first trip out.

So, has anyone got any great ideas on repairing this type of damage and what can be done to prevent this from happening again? I know I wasn't hardcore wheeling as the truck is bone stock, with only 285/75-16 tires adding a little height.

I was surprised that the mounting loop is not attached to the actual frame and is just in the wood.

Open to ideas. Thanks!

I did find when I got home that the front pass. side turnbuckle was laying in the bed. Curious I stuck my hand up to see if the camper mounting point was still there and was greated with torn wood and the mount loop at an angle. The turnbuckle was still adjusted (not loosened) as I use a jamb nut to prevent that. I haven't taken the camper off yet but I know I have some serious repairs to do. Kind of a bummer for our first trip out.

So, has anyone got any great ideas on repairing this type of damage and what can be done to prevent this from happening again? I know I wasn't hardcore wheeling as the truck is bone stock, with only 285/75-16 tires adding a little height.

I was surprised that the mounting loop is not attached to the actual frame and is just in the wood.

Open to ideas. Thanks!