Radicalfil

Advanced Member

2009 Hawk with all options except the 3 way fridge:

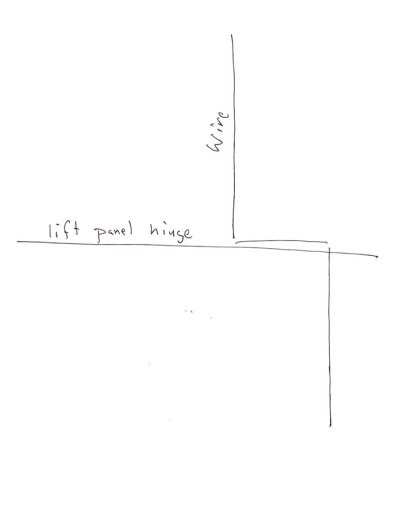

I have located wiring shorting out at the front left lifting panel. The short occurred in the wiring at the front piano hinge, as the factory wiring was duct taped to the back side of the panels. This poor design did not allow the wires to move or flex when the roof was lifted or lower and resulted in the failure of the wire and produced a short in the wiring. I stumbled on this as I blew a fused on an unrelated electric project (additional wiring loom to accommodate a ARB fridge). This also explains why my shore power plug would arc when I plugged into a 120v source. I have tried to repair these wires by splicing a 1 foot piece to allow for the extension/contraction of the roof and the wiring. I will eventually use plastic split wiring loom to protect these from contacting each other. There is not adequate room to do a real neat/good job.

There were 2 black, 1 red, 1 yellow wire at this locus. I tested the black and yellow to energize the lights and fans. Anyone know what is the other pair (red/black) are for? Does any one have a permanent fix for this situation. Anyone else have this situation and what how did you handle it?

Phil in San Leandro

I have located wiring shorting out at the front left lifting panel. The short occurred in the wiring at the front piano hinge, as the factory wiring was duct taped to the back side of the panels. This poor design did not allow the wires to move or flex when the roof was lifted or lower and resulted in the failure of the wire and produced a short in the wiring. I stumbled on this as I blew a fused on an unrelated electric project (additional wiring loom to accommodate a ARB fridge). This also explains why my shore power plug would arc when I plugged into a 120v source. I have tried to repair these wires by splicing a 1 foot piece to allow for the extension/contraction of the roof and the wiring. I will eventually use plastic split wiring loom to protect these from contacting each other. There is not adequate room to do a real neat/good job.

There were 2 black, 1 red, 1 yellow wire at this locus. I tested the black and yellow to energize the lights and fans. Anyone know what is the other pair (red/black) are for? Does any one have a permanent fix for this situation. Anyone else have this situation and what how did you handle it?

Phil in San Leandro