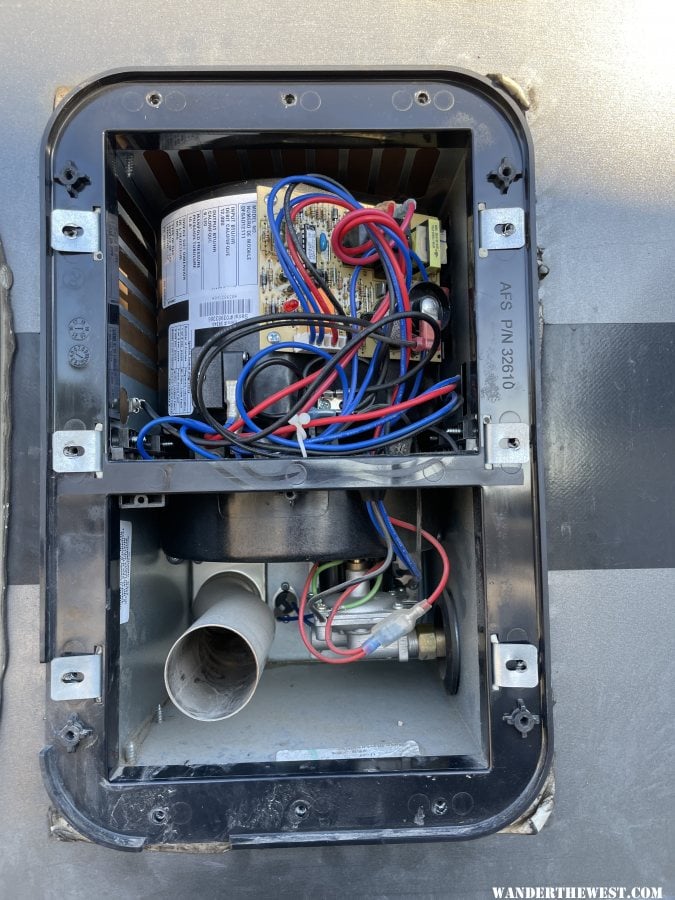

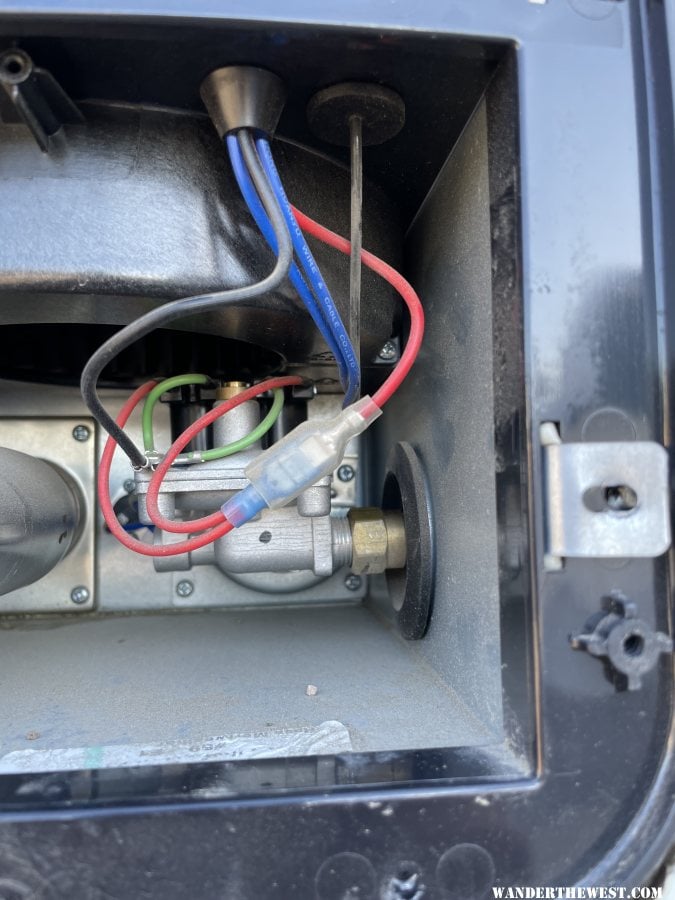

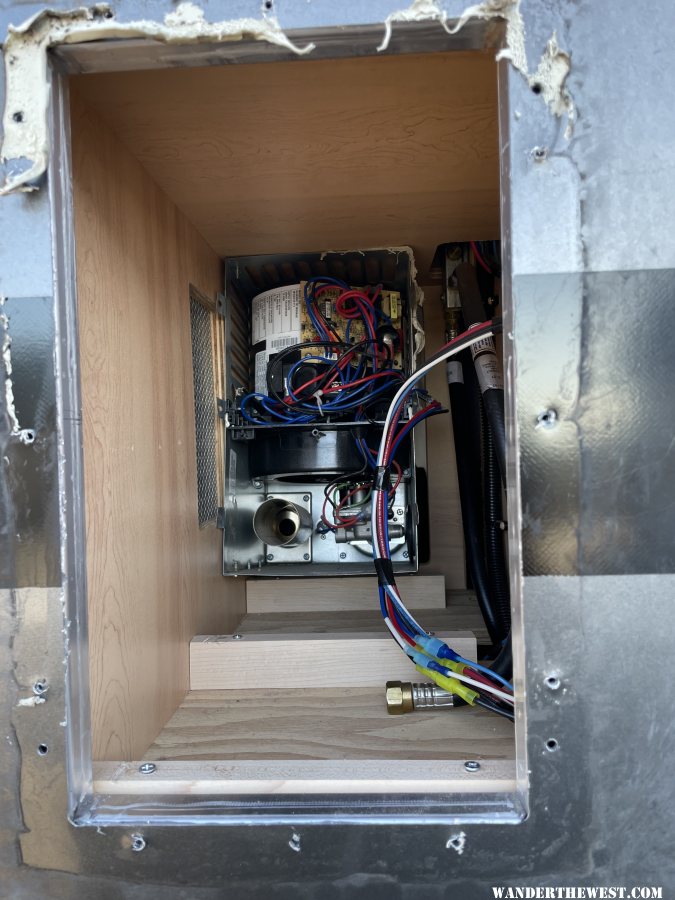

Decided to swap out the propane heater for a cheap Chinese diesel heater. To see a list of parts I purchased, see my post at

https://www.wanderthewest.com/forum/topic/25331-heating-options-for-fwc-fleet-high-elevation-winter/

In addition to those items, I also purchased...

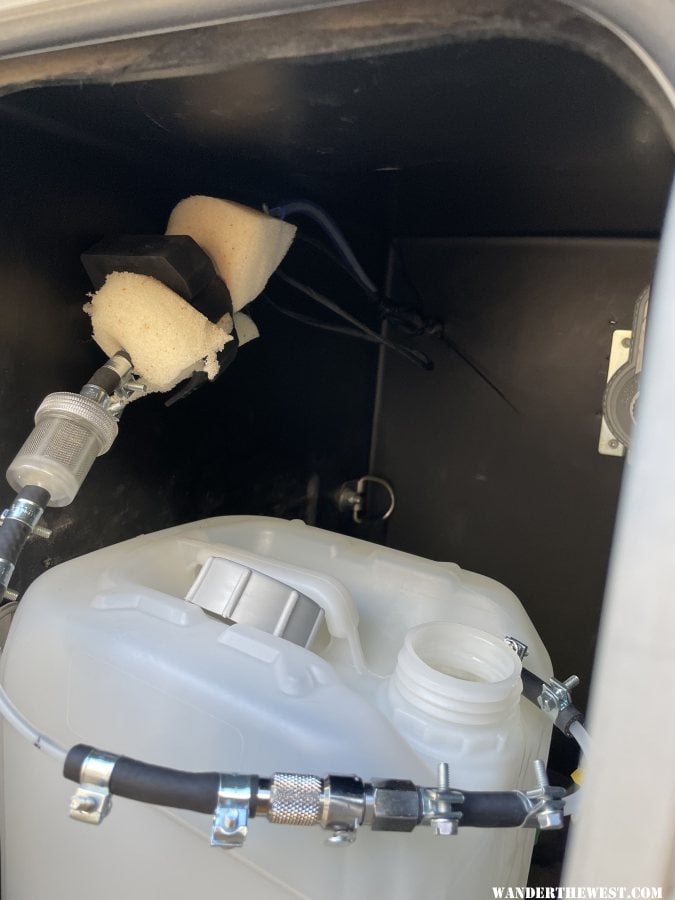

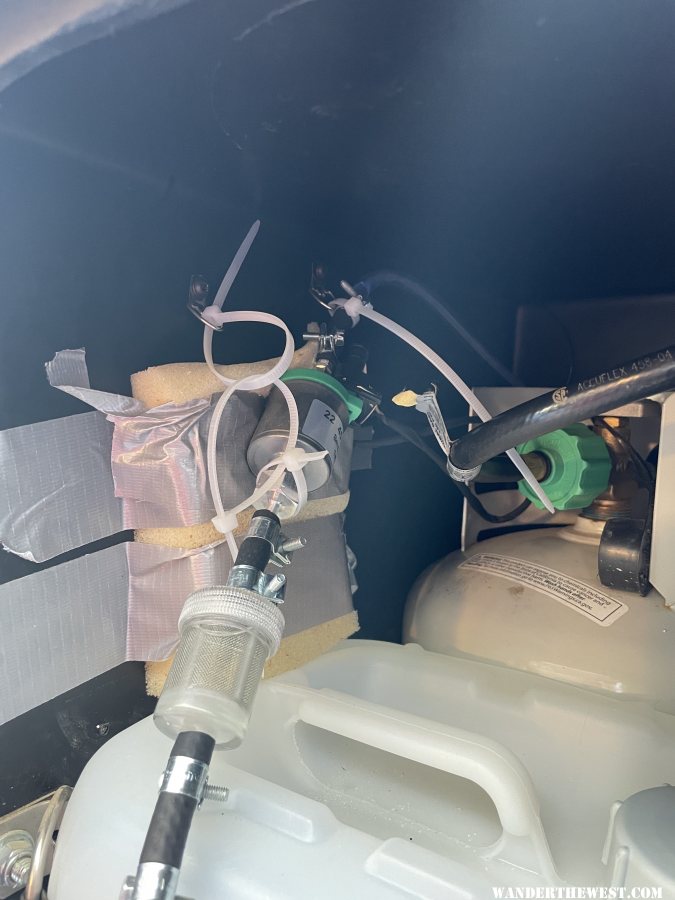

10L HDPE Jerrycan from US Plastic. This is the only 10L container I could find that would fit in the propane compartment with 1 propane tank still installed. Also purchased a standpipe and fuel line quick-disconnect kit. Still need a check valve to vent the tank. 10 Liter/2.64 Gallon Natural HDPE Jerrican with 51mm Tamper-Evident Cap | U.S. Plastic Corp.

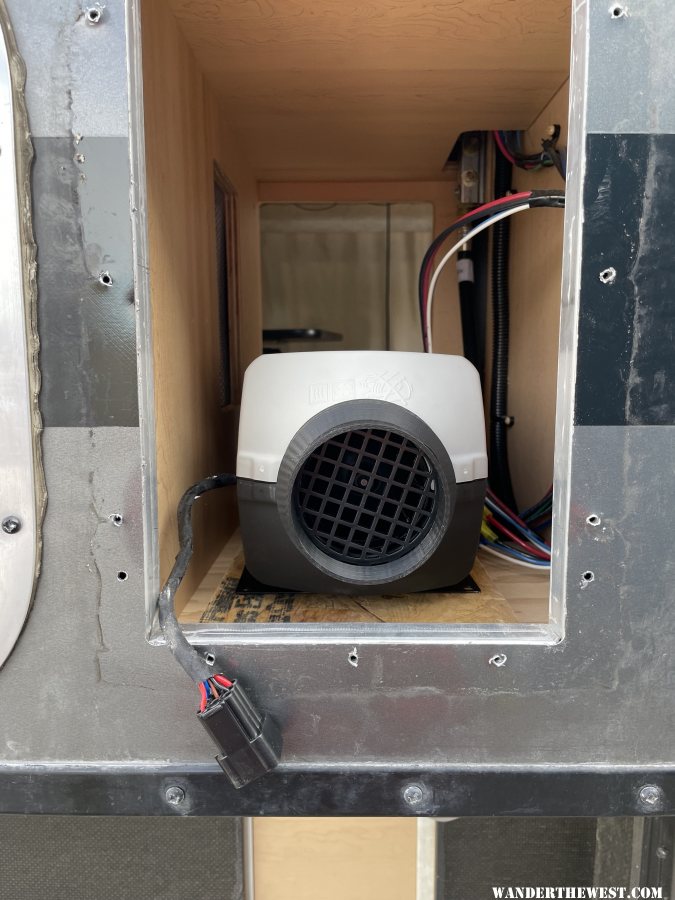

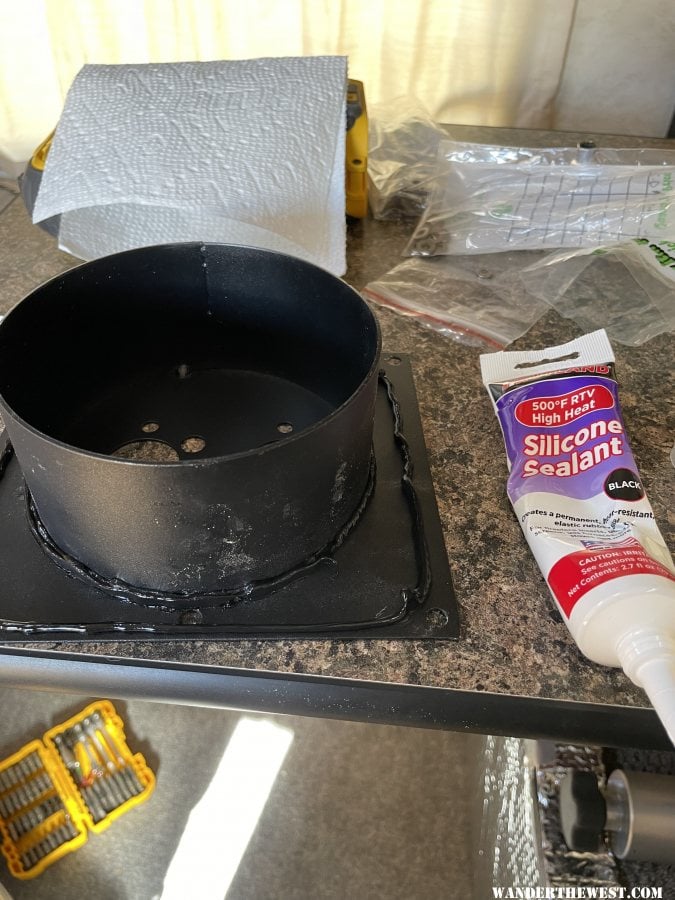

Universal turret mount, used on almost every install on YouTube. https://www.amazon.com/gp/product/B0CB66C36W/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

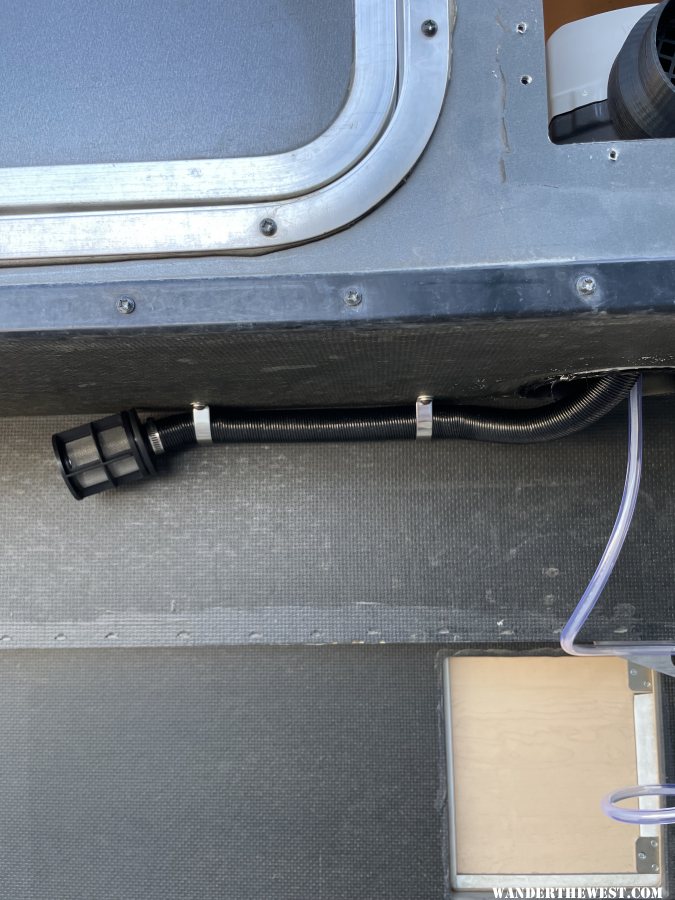

Exhaust Heat Wrap to minimize possibility of the exhaust melting the fuel line. They're very close to each other. Amazon.com

Stainless Cover. https://www.amazon.com/gp/product/B07T2ZY643/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

https://www.wanderthewest.com/forum/topic/25331-heating-options-for-fwc-fleet-high-elevation-winter/

In addition to those items, I also purchased...

10L HDPE Jerrycan from US Plastic. This is the only 10L container I could find that would fit in the propane compartment with 1 propane tank still installed. Also purchased a standpipe and fuel line quick-disconnect kit. Still need a check valve to vent the tank. 10 Liter/2.64 Gallon Natural HDPE Jerrican with 51mm Tamper-Evident Cap | U.S. Plastic Corp.

Universal turret mount, used on almost every install on YouTube. https://www.amazon.com/gp/product/B0CB66C36W/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Exhaust Heat Wrap to minimize possibility of the exhaust melting the fuel line. They're very close to each other. Amazon.com

Stainless Cover. https://www.amazon.com/gp/product/B07T2ZY643/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1