FWIW, Ive had the parts in hand on most that have been replaced, I replaced some, shops replaced others and they showed me the parts, none in my 67 1/2 T Chevy 4wd had an inner race, nor the 83 ford F250 light duty, which I ended up just replaced the entire rear end with a full floater when it needed axle shafts, and a number on 90's Suburbans. I tend to carry a lot of weight on a regular basis. When i drove pickups, I built a steel frame, steel clad utility shell on bedside tool boxes, it weighed 620 lbs empty, then I had tools, camp junk, water cans, recovery gear, ammo, shooting stuff, small camper stove and other misc stuff always along for the ride. The F 250s (had 2) with full floaters are the only axle bearings Ive never had to replace shafts or bearings in in American trucks. Somewhat limited sample size, but talking to mechanics that were working on them and other people that have had axles replaced, its not that uncommon for the semi-floaters to wear out axle shafts.

Id only suggest if one has them apart for bearings/seals or any other major work that gets the axles out, just replace them as a preventive maintenance thing IF one regularly carries heavy loads. At the point you have the shafts out, its only the cost of the shafts to replace them.

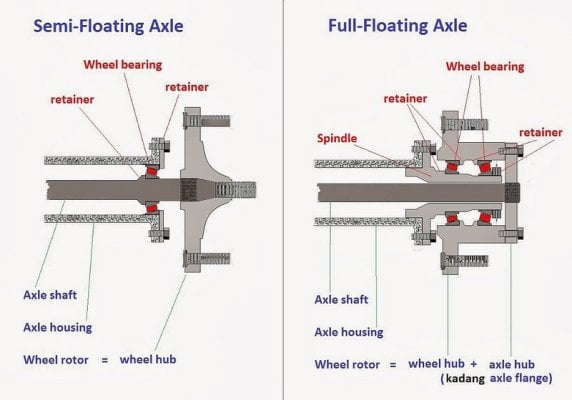

Ive seen one 1/2 T ford that broke an axle shaft on the road in Alaska, the wheel came completely off, and drug a groove in the pavement to the side of the road from the brake backing plate and anything else hanging off the end of the housing when he pulled off. I understand some older 1/2 T fords had a floater type bearing with replaceable races, but I dont know how common. The one I knew of was in a 79 Bronco I believe. I believe most of the Japanese trucks have better wheel/axle bearings than the common semi-floaters on 1/2 and light duty 3/4 ton American stuff. As someone said, they arent that great of a design, but work for most people for most of their use. Id just replace them now and then if I were going to rely on one especially for going offroad or remote country, and it carried much weight regularly. Its fairly cheap insurance. $100-ish each, depending on where you get them, I think the local parts suppliers were pricing them at $125 retail maybe? I understand handling gets sort of squirrely when the axle breaks and the wheel is gone. Fortunately I never had it happen, despite some pretty well trashed axle shafts.

Some good comments.