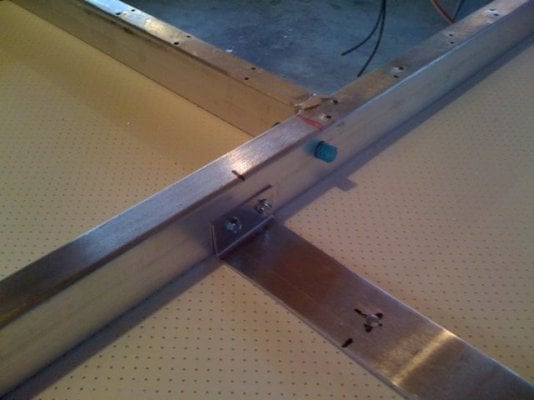

I recently became an owner of an 87 Fleet for my Tundra and decided to jump right in to some modifications...and ended up gutting the inside. There is a before picture below. Stripping all the old particle board and plywood out was very satisfying and revealing the frame and problem areas is worth it in my mind. I think I'm going to go as far as replacing the floor pack because now seems like the time. Plus, I can add a little more storage and make it custom for my Tundra. The plywood is is decent shape, but the drivers side of the floor pack is a little worked from some previous owners modifications that sacrificed the frame structure. The bottom cord of the aluminum frame was cut for the propane box and a battery? hatch leaving the 3/4 plywood doing most of the support work on that side of the camper when on the jack. See the picture below.

I'm working on modeling up the camper and interior on the computer to figure out exactly what I want. I'm going to do a dinette in the front of the camper. There are some pictures on the forum I found posted by Stan of an Eagle with a green interior that I really like the design of. I am going to reuse the stove and ice-box. What are peoples thoughts on the original Atwood furnaces? I'm not sure if mine works and like the idea of a simple Wave 3 heater. I don't really care about running heat while sleeping, but it would be nice in the evenings and in the morning.

I'm clueless when it comes to wiring the camper. I don't have the money to do anything fancy right now but would like to wire for the future. I would like to have a plug on the outside of the camper for an extension cord. Solar sounds appealing. What type of panels/converters etc. are needed? Can someone point me in the right direction for some "basic camper wiring"?

I have been searching and finding all sorts of good info on the forum. I'm open to all advice as this is my first camper.

I'm working on modeling up the camper and interior on the computer to figure out exactly what I want. I'm going to do a dinette in the front of the camper. There are some pictures on the forum I found posted by Stan of an Eagle with a green interior that I really like the design of. I am going to reuse the stove and ice-box. What are peoples thoughts on the original Atwood furnaces? I'm not sure if mine works and like the idea of a simple Wave 3 heater. I don't really care about running heat while sleeping, but it would be nice in the evenings and in the morning.

I'm clueless when it comes to wiring the camper. I don't have the money to do anything fancy right now but would like to wire for the future. I would like to have a plug on the outside of the camper for an extension cord. Solar sounds appealing. What type of panels/converters etc. are needed? Can someone point me in the right direction for some "basic camper wiring"?

I have been searching and finding all sorts of good info on the forum. I'm open to all advice as this is my first camper.