Star152

Senior Member

- Joined

- Jan 5, 2007

- Messages

- 188

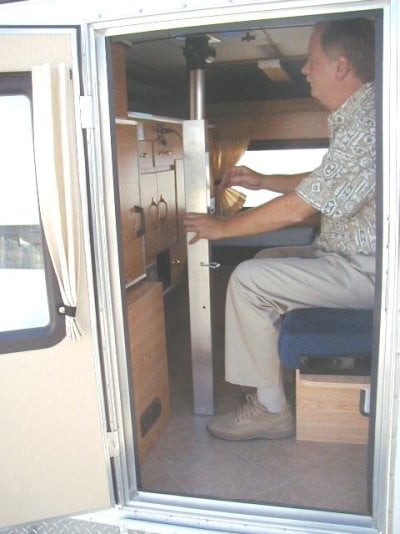

I want to thank BUZZ for giving me the inspiration for thinking about and creating the roof lift and lowering device. I used many items that I already had and the cost of the items I needed was about $15.00 and OSH. Items needed.

1. 1 pair of aluminum crutches

2. 4 hose clamps

3. ¾ inch PVC pipe 2 pieces cut into 7 inch pieces (check if the crutch fits inside the PVC pipe and slides freely)

4. ¾ inch square dowel cut into 2 7 inch pieces

5. 2 double wheel pulleys

6. A piece of metal strap.

7. (1) 6 inch long bolt and nut to replace the one for the handle

Take one crutch and remove the underarm support and handle.

Take the other crutch and remove the adjustable foot you will no longer need this.

Using a long piece of wood knock out the plastic cap at the other end of the adjustable foot support.

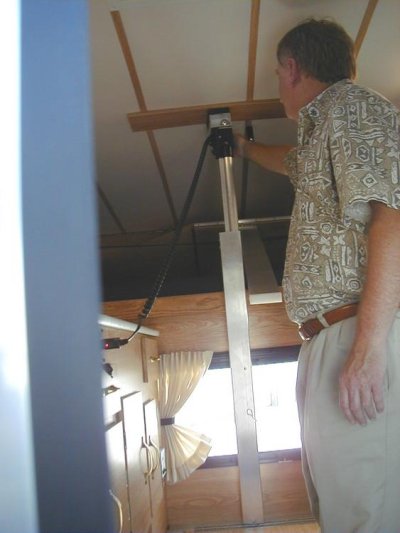

Drill a hole to fit a bolt and nut to hold pulley.

Attach the PVC pipe and wood using hose clamps see photo.

Take the other crutch and drill holes and enlarge to fit a larger bolt for strength where the arm support was removed. Slide the crutch with the foot into the PVC pipe.

Secure the saved handle with the larger bolt and tighten.

Shape a piece of metal strap around the plastic handle and drill a hole to fit the other pulley.

Drill a hole and screw down to hold the pulley parallel to the crutch.

Tie one end of the rope to the handle where the pulley is attached. Route the rope through the pulley so that the rope ends up so you can pull up the rope to raise the crutch. Now you are done.

Raise and lower the camper top to your hearts content.

NOTE on my camper the front is higher than the rear. I raise the foot section to meet the roof support and pull the rope to raise the top. Have fun……it works great.

1. 1 pair of aluminum crutches

2. 4 hose clamps

3. ¾ inch PVC pipe 2 pieces cut into 7 inch pieces (check if the crutch fits inside the PVC pipe and slides freely)

4. ¾ inch square dowel cut into 2 7 inch pieces

5. 2 double wheel pulleys

6. A piece of metal strap.

7. (1) 6 inch long bolt and nut to replace the one for the handle

Take one crutch and remove the underarm support and handle.

Take the other crutch and remove the adjustable foot you will no longer need this.

Using a long piece of wood knock out the plastic cap at the other end of the adjustable foot support.

Drill a hole to fit a bolt and nut to hold pulley.

Attach the PVC pipe and wood using hose clamps see photo.

Take the other crutch and drill holes and enlarge to fit a larger bolt for strength where the arm support was removed. Slide the crutch with the foot into the PVC pipe.

Secure the saved handle with the larger bolt and tighten.

Shape a piece of metal strap around the plastic handle and drill a hole to fit the other pulley.

Drill a hole and screw down to hold the pulley parallel to the crutch.

Tie one end of the rope to the handle where the pulley is attached. Route the rope through the pulley so that the rope ends up so you can pull up the rope to raise the crutch. Now you are done.

Raise and lower the camper top to your hearts content.

NOTE on my camper the front is higher than the rear. I raise the foot section to meet the roof support and pull the rope to raise the top. Have fun……it works great.