Stan@FourWheel

Senior Member

We have finally done it. Yea !

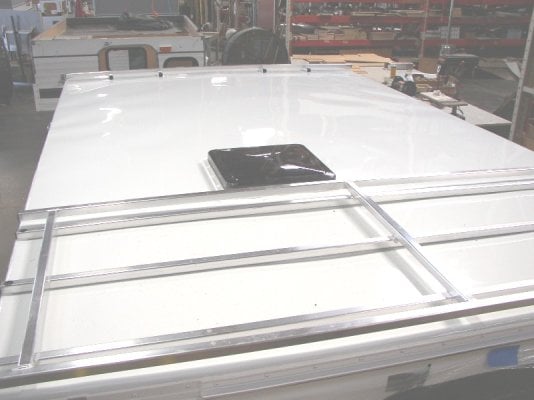

We have made the transition over to the new four wheel pop-up camper roofs.

FWC is now using a one piece aluminum roof.

No more attachment screws !

No more seam down the middle !

The smooth (non-textured) aluminum roof should be easier to keep clean and the snow might be easier to remove since the roof is flat & smooth (snow should slide off a bit easier).

For sure it will a big improvement to helping avoid roof leaks as the campers age.

For the last 35 years we used the screws to attach the camper roof skin to the roof frame.

This worked OK, but the screws over the years would sometimes rust, back out over time, or the rubber washers could dry out.

We are excited about this new change & think that this new roof will be a BIG selling point to consider buying an FWC over another camper manufacturer.

Happy Camping !

.

.

We have made the transition over to the new four wheel pop-up camper roofs.

FWC is now using a one piece aluminum roof.

No more attachment screws !

No more seam down the middle !

The smooth (non-textured) aluminum roof should be easier to keep clean and the snow might be easier to remove since the roof is flat & smooth (snow should slide off a bit easier).

For sure it will a big improvement to helping avoid roof leaks as the campers age.

For the last 35 years we used the screws to attach the camper roof skin to the roof frame.

This worked OK, but the screws over the years would sometimes rust, back out over time, or the rubber washers could dry out.

We are excited about this new change & think that this new roof will be a BIG selling point to consider buying an FWC over another camper manufacturer.

Happy Camping !

.

.