I just returned from a 8 day trip to Baja. I first put my new to me 2006 Hawk on my new 2011 F-250 and did 2 “little” trips for a couple days each, without much off-roading. On both trips my turnbuckles kept coming loose (especially in front) and I just thought this was typical, especially when new. Prior to Baja I made sure they were all tight (though not over tightened) and headed south. On the first day, I noticed at El Rosario that one front one was quite loose and I had not been off road. By Catavina (with a little off road) the 2 front ones were quite loose and the back a bit. I tightened them a bit and in the morning looked under the truck, where I could see the bed was pulled up in the area of the two front mounts and that the metal was actually starting to tear. In Guerrero Negro, I went to a truck place that created two metal plates that they installed under the truck bed. This was a decent idea, but did not really deal with the ripping of the metal. They then tightened the turnbuckles, but by the next day they were loose again. My guess was that if the metal would pull up more, the buckles would become loose, even if the buckles themselves had not loosened. I put on some ratchet straps to anchor the front two jack mounts to the frame to give me a bit of piece of mind, though both straps eventually broke before I got home and had to be redone. I did make it back to San Diego ok, but now I am trying to figure out what repairs to make and what to do to prevent this in the future. I absolutely love my Hawk other than these mounting issues.

First, what do you folks think of the metal deflecting and tearing? Is this common? Do you think this was a problem at how the bed was made/welded? I know people with 4Wcampers who do serious offroad stuff and they have never had this problem.

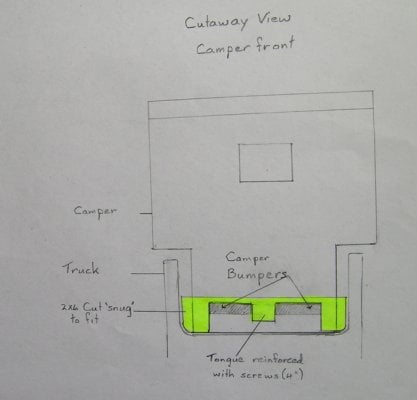

Second, I am considering doing the “bolt thru” mounting system advocated by some on this list. Are people still doing this and if so, how do you like it? How many locations do you bolt thru and which type of bolts do you use? What size plates do you put underneath the truck bed? I spoke to Jeff at ATC and he seemed to advocate this approach if I am going to go offroad a lot and not going to take my camper off very much, which I do not plan to do. My camper is on 1 inch of boards to elevate the camper so that it clears my cab (the Ford cab is higher than others). Is this a problem for the bolt thru option?

I could also do the bolt on approach and still have turnbuckles for a redundant backup option. Is there a point to getting the truck bed fixed/welded if I am going to do the bolt thru option? I assume I need to fix the truck bed (or maybe put in bigger plates) if I am still going to use turnbuckles. Any thoughts or other suggestions? Thank you.

PS – The plate you see in the photo is what the person in Guerrero Negro put on. I think it will keep the bolt from pulling through the truck bed, but it doesn’t seem like it really addresses the tearing of the metal.

First, what do you folks think of the metal deflecting and tearing? Is this common? Do you think this was a problem at how the bed was made/welded? I know people with 4Wcampers who do serious offroad stuff and they have never had this problem.

Second, I am considering doing the “bolt thru” mounting system advocated by some on this list. Are people still doing this and if so, how do you like it? How many locations do you bolt thru and which type of bolts do you use? What size plates do you put underneath the truck bed? I spoke to Jeff at ATC and he seemed to advocate this approach if I am going to go offroad a lot and not going to take my camper off very much, which I do not plan to do. My camper is on 1 inch of boards to elevate the camper so that it clears my cab (the Ford cab is higher than others). Is this a problem for the bolt thru option?

I could also do the bolt on approach and still have turnbuckles for a redundant backup option. Is there a point to getting the truck bed fixed/welded if I am going to do the bolt thru option? I assume I need to fix the truck bed (or maybe put in bigger plates) if I am still going to use turnbuckles. Any thoughts or other suggestions? Thank you.

PS – The plate you see in the photo is what the person in Guerrero Negro put on. I think it will keep the bolt from pulling through the truck bed, but it doesn’t seem like it really addresses the tearing of the metal.