Man that really sucks!

I've done some serious 4x4 driving and haven't had a single problem with the eye bolts in the bed of my truck, which raises the question - how did you mount the eye bolts in your truck?

The damage has already been done to your truck and copying lqhikers mount may be the best bet. I'm including the following description for the benefit of others who may mount their own eye bolts.

I used 1/2" diameter, galvanized, shoulder, eye bolts with 2" square, 1/8" thick, galvanized washers on the top and bottom of the truck bed. Because the corrugation of the ribs in my truck are less than 2" wide, I was careful to select a location in the middle of a corrugation rib, then I used a grinder to trim the 2" washers such that all the mating surfaces between the washers and the truck bed were flat and smooth. That is, I placed the top washer in a valley of the corrugation, trimmed a little of the left and right of the washer such that when it sat in the corrugation valley, the bottom, and both sides of the washer were flat with the truck bed's corrugation. I'm sorry I don't have pictures but in ascii art it looks like this:

Code:

Top washers before grinding/fitting.

_______

|_______|

Top washers after grinding/fitting.

_______

\_____/

Truck bed corrugation.

_____ _____

/ \_____/ \

After that, I painted the truck bed steel exposed by the drill with a rust inhibiting paint. I used the same paint on the top washers which I had ground to fit. I finished it with an unmodified 2" square, 1/8 thick galvanized, flat washer on the bottom and a galvanized nut and lock washer.

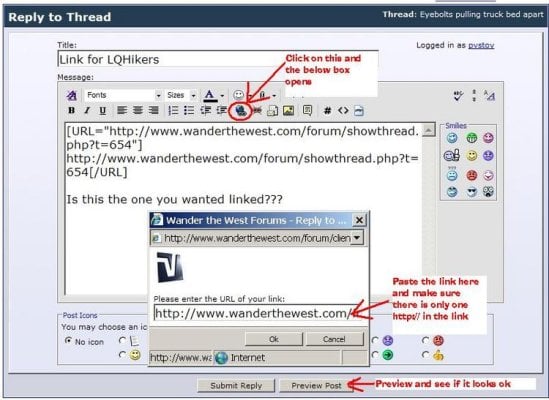

As far as where to place the truck bed eye bolts, more can be found at

http://www.wanderthewest.com/forum/showthread.php?t=1009