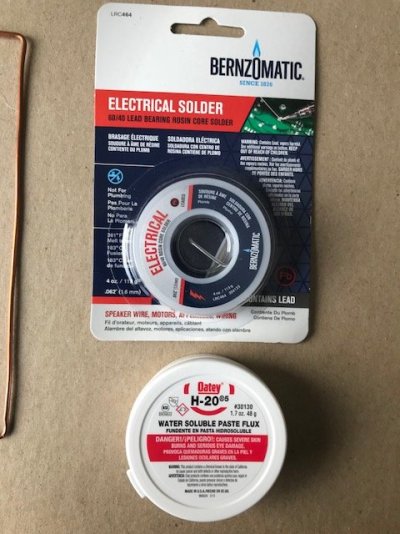

Well I went all in... ordered the batteries and the sundry items needed (with the help of this thread starter! BIG Thanks). Have to get the higher wattage iron, flux core solder and flux and a shrink wrap hot gun (Craig's list $15) .... I have a hot glue gun to hold things together.

I have been on the sidelines watching this idea...thinking it was too much for me without the electronic background but with some help I think it is a great opportunity to improve the camper....save enough weight to equal a big dog and her food! That is the beauty of WTW... sharing ideas and expertise! The stuff should all be here in 2-3 weeks and then I will repost with the assemble table photos and requests for advice. A great winter time project.

I have been on the sidelines watching this idea...thinking it was too much for me without the electronic background but with some help I think it is a great opportunity to improve the camper....save enough weight to equal a big dog and her food! That is the beauty of WTW... sharing ideas and expertise! The stuff should all be here in 2-3 weeks and then I will repost with the assemble table photos and requests for advice. A great winter time project.