JHanson

Senior Member

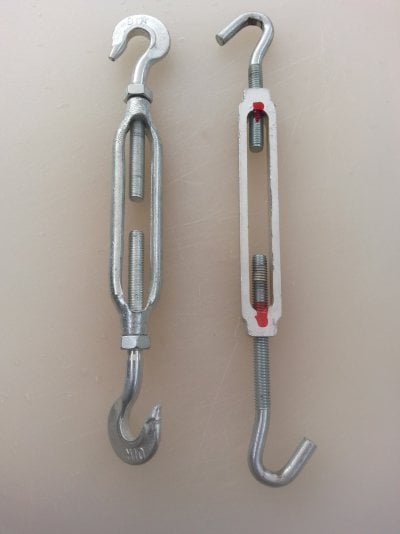

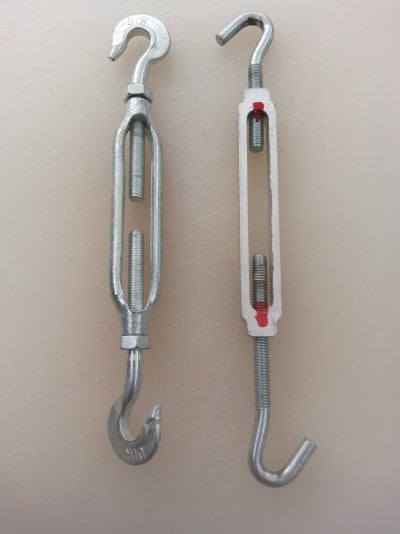

A turnbuckle should not break during an emergency lane-change maneuver. There's a difference between a safe failure point and a weak spot. I believe the stock turnbuckles are a weak spot - one of the very very few items I find inadequate on the FWC.I agree with you completely. I wouldn't be replacing those turnbuckles with stronger ones. Being a half @$$ed engineer, you're just moving the failure point somewhere else like truck bed mount, the bed itself, or the camper. In a pinch you could use a tiedown strap if you had to if you lost a turnbuckle to get home or to the next hardware store. After reading this thread, I like my external torklift tie downs better all of the time.