Great minds think alike. I had been trying to figure out how to run heavier 8 gauge wire from the front of the camper to the controller near the battery box. The obstacle was the thickness of the cable wouldn't go down behind the trim piece on the bed platform and clear the frame. And then this morning, I read ski3pin's post about routing a channel on the backside of the plywood behind the trim and it all came together. My camper was wired for solar so aside from about a 6-7 foot run from the ceiling box to the front of the camper, the wire is now 8 gauge instead of 12.

I didn't take a picture of the routed panel but essentially, I used a straight bit and notched the bottom of the plywood piece FWC installs behind the trim along the side of the bed platform. The 8 gauge cable sits in that groove.

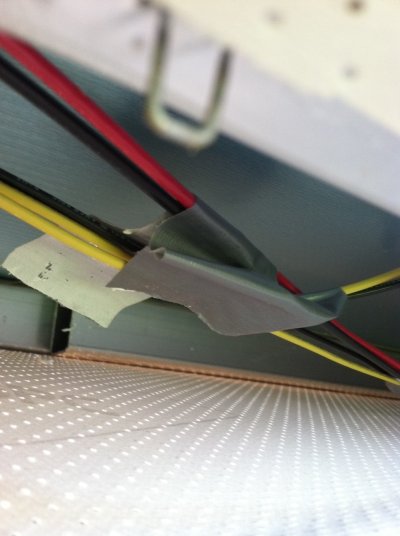

I then removed the wood that supports the platform when extended, and cut a hole in the end. The wire exits the groove in the plywood and angles out until it passes thru the support. The bed platform slides on top so is not affected at all.

Using reducing butt connectors, I connected the 8 gauge wire to the 12 gauge coming from the roof and heat shrinked it all together. The connection now hides behind the carpet so its out of sight.

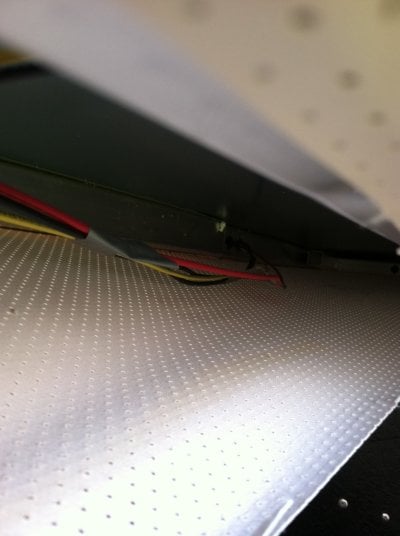

Once the bed platform is on, you can see just a bit of cabling. It runs down in the gap next to the cabinet, over the water tank and into the battery box.

Thanks to everyone who contributed to this thread. I will be installing two 100w rigid panels in the next few weeks, and I will document that process as well.

Cheers