2018 Hawk Front Dinette

"Pre-wired" for Solar

No Factory Solar Controller/Panel Installed

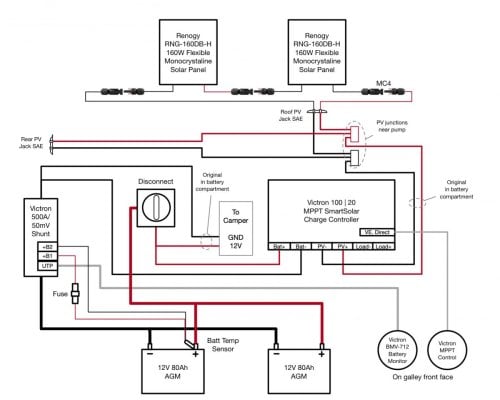

Project - Install the following:

Victron MPPT 75/15

160W roof mounted panel

To those that have come before me...

I pulled out the wiring from below the sink counter and have located the solar wire bundle.

Item 1:

There are two 3-wire push connector wall nuts (+ / - wires). Only two of the three wires are labeled. One says "Solar Battery", the other says "Rear Solar".

-Is the third set the wires coming from the roof solar plug?

-I assume the "Solar Battery" are the same wires that are coiled in the battery box. Can anyone confirm?

Item 2:

Along with this bundle, there is a black/white wire pair that simply terminate in a butt connector. The wires are labeled "Load".

-What are these wires?

I can post pictures later if it would be helpful.

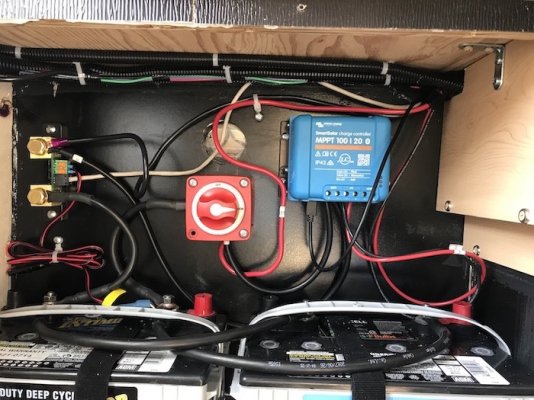

I've already successfully installed a Victron BVM-712 in the battery box and plan to mount the MPPT in the battery box as well...just need to make sure I understand how the "pre-wired" solar is configured.

Thanks.

"Pre-wired" for Solar

No Factory Solar Controller/Panel Installed

Project - Install the following:

Victron MPPT 75/15

160W roof mounted panel

To those that have come before me...

I pulled out the wiring from below the sink counter and have located the solar wire bundle.

Item 1:

There are two 3-wire push connector wall nuts (+ / - wires). Only two of the three wires are labeled. One says "Solar Battery", the other says "Rear Solar".

-Is the third set the wires coming from the roof solar plug?

-I assume the "Solar Battery" are the same wires that are coiled in the battery box. Can anyone confirm?

Item 2:

Along with this bundle, there is a black/white wire pair that simply terminate in a butt connector. The wires are labeled "Load".

-What are these wires?

I can post pictures later if it would be helpful.

I've already successfully installed a Victron BVM-712 in the battery box and plan to mount the MPPT in the battery box as well...just need to make sure I understand how the "pre-wired" solar is configured.

Thanks.