meandmydog

Member

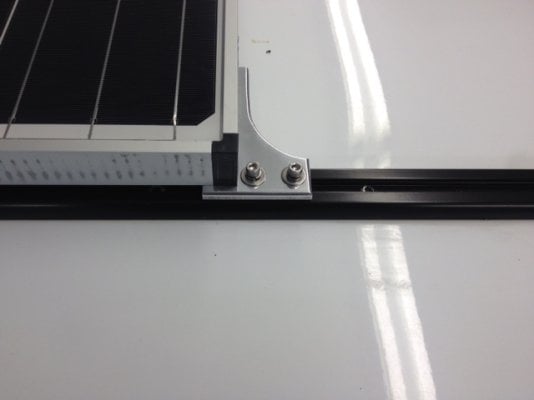

I have a question on what is the best way to attach cross bars to Yakima tracks. I am installing 2 100 watt solar panels on the roof of my camper. I've got the tracks installed and I'm using 1" square aluminum tubing for cross bars. The solar panels are through bolted to the 1" square with 1/4" stainless steel bolts with lock washers. That's all good. My big agonizing question is how to attach the 1" square tubing to the Yakima tracks. I bought 1-1/2" and 2" stainless steel bolts and planned on through bolting into the "A" nuts that are designed to run in the track. The 1-1/2" only engage a couple of threads so they're too short. The 2" bottom out in the bottom of the track before tightening up but I could put a 1/4" spacer under the bolt head to take up the slack. My main question is how to make sure the bolts don't vibrate loose going down the road. I planned on using Lock tight thread lock blue or red. I've thought about putting a flat washer and a lock washer under the head of the bolt in addition to the thread lock. I've read on this blog and others where people put bolts in the tracks upside down like elevator bolts or others. I kind of like this idea because then you can put a lock nut on top and don't have to worry about the bolt bottoming out in the bottom of the track and not having a lock nut.

So I would like to see what all of the people here have used in the real world. I'm sure there are some great ideas that have been used for thousands of miles. I really need to be certain that my solar panels don't loosen up and come flying off going down the highway.

Here's a picture of my setup. Thanks in advance for all the advise.

So I would like to see what all of the people here have used in the real world. I'm sure there are some great ideas that have been used for thousands of miles. I really need to be certain that my solar panels don't loosen up and come flying off going down the highway.

Here's a picture of my setup. Thanks in advance for all the advise.