Thanks Rusty. Made it back to Miami with no issues from KY. I had picked up some stainless chain, turnbuckles and shackles from a rigging store before I left so the Alaskan was secured from the jack plates to the flat bed grab rail and for the most part stayed true.

I will post some pics as soon as I resize them, what software works best for you?

My Alaskan was delivered to the first owner 3/15/2010. Interesting guy and had some very definite ideas on what he wanted based on living in Colorado. It had sat in a three sided barn for a least a year in KY. Very clean interior and a wash took care of exterior

Its an 11' slide in cab over which Bryan says is the only one he's made to date. 7" longer front dinette and wider bed 55 x 81.

He opted for floor heating with built in pex tubing for anti freeze in lieu of furnace, The anti freeze is heated by a small propane fired heat exchanger. He stated while it worked well there were mixed results. it was plumbed so as to heat the exterior sections of the floor under the cabinets first then the exposed interior floor. I will reverse that to see if I can get better results

The extra space by eliminating the furnace was converted into shelving for storage

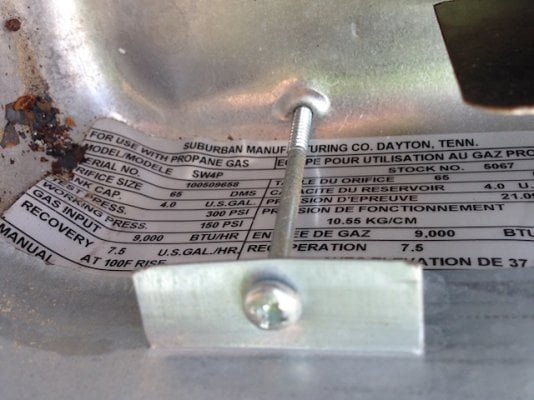

The hot water heater was eliminated and replaced by an external 115 VAC electric instant hot plumbed into the sink and powered by generator. Dual fans, 3 burner cook top no oven, NovoKool 4500 and of course a thetford.

My first work scope is a platform extension for the flat bed not only to support the camper but to put some steel between the camper and my back up skills.

After that comes a semi permanent securing of the camper to the flatbed.

I want to secure directly from the camper to the flat bed, eliminating the jack pads etc and would be interested in ANY feedback on that and dunnage under the camper. I want air movement under the camper so the transfer of heat or cold soaking of the metal flatbed is minimized plus to allow any moisture to escape

For the trip back I had purchased 1" x 4" placed along the exterior footprint of the camper to keep it off the flatbed diamond. The cab over clearance is 7 1/2".

Interesting side note was that while driving 65-70 I could place my hand on the cabover and feel the popup vibrate up and down 1-2" which is what has caused some chaffing marks on the exterior of the front hatch.

Once the mounting and securing is complete I will have some aluminum storage boxes made for above and under the flatbed